JSGW-1050 Nano Thermal Insulation Board

The nano thermal insulation board is formed by using light weight, inorganic nano SiO 2 and ceramic fiber with extremely low thermal conductivity as raw materials and aluminum foil with high reflectivity as bottom material, adopting a single-layer composite structure to be continuously coated and matched with a pressing and baking process, and has the thermal conductivity smaller than that of static air, and the thermal insulation performance is about 4 - 6 times better than that of the traditional thermal insulation material, so the nano thermal insulation board is the thermal insulation material with the best performance so far.

The nano thermal insulation board has ultra-low thermal conductivity, can greatly save energy compared with the traditional thermal insulation material, and has a pipe diameter of 150 mm.. For example, for pipelines with a temperature of 600 degrees, when the thickness is only one third of the thickness of conventional mineral wool, 1,400 degrees of electricity is saved per meter of pipeline per year, and the total length of 1,000 meters of pipeline saves about 1.4 million degrees of energy per year.

Characteristics and functions

High temperature resistance - long-term use temperature of 400 ~ 1000 degrees

Thermal conductivity - 2 ~ 10 times lower than the conventional thermal insulation material, only 0.052 w / m k at 800 degrees

Durability - can be used as insulation permanent layer, service life of more than 5 ~ 10 years

Safety and environmental protection - pure non-polar material combination, good thermal stability, no release of any harmful substances

Economic analysis - the price is lower than 50 % of foreign similar products, 10 ~ 30 % energy saving than conventional materials

Main technical performance indicator.

|

Product Name

|

JSGW-1050 Nano Thermal Insulation board

|

Inspection Standard

|

|

|

Product Code

|

JSGW-1050

|

|

|

|

Melting Point

|

≥1200℃

|

|

|

|

Use Temperature

|

1050℃

|

|

|

|

Density (±10%)

|

320kg/m3

|

GB/T17911-2006

|

|

|

Specific Heat Capacity(400℃)

|

0.8kJ/kg.k

|

YB/T4130-2005

|

|

|

Compressive strength(Compression10%)

|

0.3MPa

|

GB/T 13480-1992

|

|

|

Linear shrinkage(800℃)

|

2.0%

|

GB/T17U911-2006

|

|

|

Thermal conductivity(w/m.k)

|

70℃

|

0.019

|

YB/T4130-2005

|

|

200℃

|

0.021

|

||

|

400℃

|

0.024

|

||

|

600℃

|

0.031

|

||

|

800℃

|

|

||

|

0.040

|

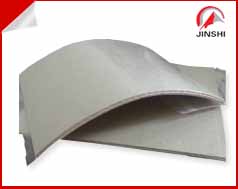

Nano thermal insulation board has excellent thermal insulation performance, because of its thermal conductivity is very small, only 1 / 3 ~ 1 / 4 of the traditional thermal insulation materials, therefore, under the condition of guarantee the same cold surface temperature insulation thickness can be very thin, that is to say, under the condition of insulation thickness cannot be too thick, can the cold surface temperature as far as possible to the lowest, because the site thermal conditions are complex and changeable, the thermal insulation effect under the same conditions is not the same.

|

Thickness(MM)

|

Hot Surface Temperature(℃)

|

1000℃ Heat dissipation w/m

|

||||||||||

|

200

|

300

|

400

|

500

|

600

|

700

|

800

|

850

|

900

|

950

|

1000

|

||

|

3

|

85

|

117

|

146

|

175

|

210

|

239

|

269

|

288

|

308

|

319

|

339

|

9489

|

|

5

|

68

|

91

|

115

|

138

|

161

|

184

|

215

|

223

|

240

|

257

|

265

|

5849

|

|

7

|

58

|

77

|

95

|

116

|

136

|

155

|

176

|

190

|

197

|

212

|

227

|

4394

|

|

10

|

50

|

65

|

79

|

94

|

112

|

128

|

146

|

158

|

164

|

177

|

183

|

2999

|

|

15

|

|

|

64

|

75

|

87

|

103

|

117

|

122

|

132

|

137

|

147

|

2087

|

|

20

|

|

|

|

65

|

74

|

85

|

96

|

104

|

113

|

117

|

126

|

1604

|

|

25

|

|

|

|

|

66

|

75

|

85

|

92

|

95

|

103

|

111

|

1305

|

|

30

|

|

|

|

|

|

68

|

76

|

83

|

86

|

93

|

96

|

1025

|

|

35

|

|

|

|

|

|

|

70

|

76

|

78

|

85

|

87

|

887

|

|

40

|

|

|

|

|

|

|

|

70

|

73

|

78

|

81

|

781

|

|

45

|

|

|

|

|

|

|

|

|

68

|

73

|

76

|

698

|

|

50

|

|

|

|

|

|

|

|

|

|

69

|

71

|

|

|

632

|

Metallurgy: ladle, ladle, tundish, converter, torpedo ladle

Machinery: industrial furnace, electric furnace, furnace door, furnace cover

Automobile: engine heat shield, catalytic exhaust pipe

Petrochemical: cracking furnace, conversion furnace, heating furnace

Power: boilers, steam turbines, pipelines

Building materials: ceramic furnace, rotary furnace

Use effect:

Reduce that thickness of the heat insulation layer

Reduced heat storage

Reduce heat dissipation

Temperature homogenization

Rankings of similar articles

- Nano thermal insulating plate

- Jsgw - 1100 nano thermal insulation board

- Jsgw - 950 NanoThermal Insulation Board

Latest information

- Recruitment (Domestic Sales, E-Commerce)

- Italian customers come to visit our company and reach in-depth cooperation

- JinShi participate in 2016 international wall roofing materials production and equipment Expo

- Six Excellent Properties of Nano Aerogel Insulation Felt

- Nano Aerogel Insulation Felt is known as

- Comparison of thermal insulation effect of nano aerogel thermal insulation felt and other thermal insulation materials in petroleum pipeline

- The nano aerogel thermal insulation felt has good thermal insulation performance, superhydrophobic property, long service life, compression resistance and easy installation and maintenance

- Why not many manufacturers of nano aerogel insulation felt on the market?

- Characteristics and preparation process of nano aerogel insulation felt

- Can nano heat shields be used on ships and vessels and how?

Contact us

hotline:

86-132-806-65866

The phone:86-0533-2266502

add:Shandong zibo hi-tech development zone.