Characteristics and preparation process of nano aerogel insulation felt

With the increasing shortage of energy and rising energy prices, energy conservation and consumption reduction is imperative. the traditional thermal insulation materials can not meet the increasing heat insulation requirements. in 2006, nano aerogel thermal insulation felt was developed in China, which can effectively limit the heat convection in the gas phase. In addition, its solid phase thermal conductivity is very small because its solid phase part is also a network structure formed by nanoscale SiO _ 2 wall shell. Therefore, the structure of the material determines its super thermal insulation performance, especially at high temperature, such as the average temperature of 500 degrees, aluminum silicate fiber thermal conductivity of 0.153 w / m k, and nano aerogel thermal insulation felt thermal conductivity of only 0.05 w / m K..

Thermal insulation principle of 1 nm aerogel thermal insulation felt

Existing theories and experiments show that the thermal conductivity of the object depends on its size, for example, the thermal conductivity of SiO _ 2 solid ( Shi Ying, axial ) is 41.6 WM - 1k - 1, the thermal conductivity of si _ 02 gel powder is 0.035 WM - 1k - 1, and the thermal conductivity of SiO _ 2 aerogel is 0.014 - 0.016 WM - 1k - 1; When the diameter of inorganic fiber is reduced from 15 μ m to 3 μ m, the thermal conductivity of mineral fiber cotton is reduced by 12 % and that of glass fiber cotton is reduced by 6 %.

Accord to that micro-nano scale heat transfer, when the medium scale is reduced to the micro-nano scale, the heat conductor can become a thermal insulator. That is to say, when the size of the medium is smaller than the average free path of the thermal carriers ( molecules, atoms, electrons, phonons, photons, etc. ), the scale effect and interface effect are obvious, and the thermal contact resistance increases. The thermal conductivity decreases and the heat transfer capability decreases. Therefore, the important difference between microscale heat transfer and macroscopic heat transfer lies in the dependence of parameters such as thermal conductivity and specific heat capacity on the scale of medium.

The main raw material for preparing the nano aerogel thermal insulation felt is the large hole containing the rice flour material. Due to the high porosity, the thermal conductivity is low; According to the international standard iso 2245 - 1972, the porosity of the insulation product is at least 45 %, the porosity of the general insulation product is 70 %, and the porosity of the large hole containing rice flour material is 1.8 mlg - 1. So that that ultra-low heat conduction heat insulation board can be produce by accommodating the rice flour material through the large hole.

Properties of 2 nm aerogel insulation felt

As mentioned above, the most outstanding performance of the nano aerogel insulation felt is the insulation performance under high temperature conditions. The results of the tests we have done are classified and analyzed with reference to the data of some foreign products

( 1 ) thermal conductivity

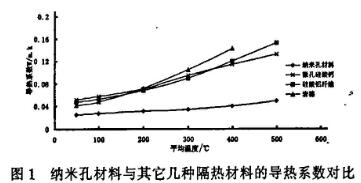

Nano aerogel thermal insulation felt has a very small thermal conductivity, especially in high temperature conditions, its thermal conductivity compared with several other commonly used marine thermal insulation materials has a very high advantage ( figure 1 )

As can be seen from fig. 1, its thermal conductivity at high temperature is about 1 / 3 of that of several other thermal insulation materials.

( 2 ) bulk density

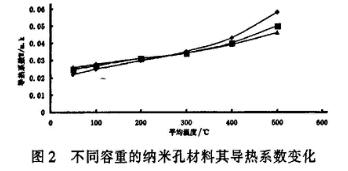

Some variations in thermal conductivity at different bulk densities are reflected in fig. 2. When the bulk density decreases, the nanoporous structure becomes loose and some voids form micron size, which makes the heat convection of air accelerate at high temperature. Therefore, the thermal conductivity increases accordingly. However, if the bulk density increases to a certain value, although the heat convection of the air at high temperature is prevented, the heat conduction in the solid phase becomes obvious and the heat conductivity begins to increase again. Therefore, the bulk density of some foreign nano aerogel insulation felts is usually between 160 kg / m3 and 256 kg / m3 ( i.e. 10 ~ 16 PCF ). The bulk density and thermal conductivity of the materials should be considered when applied to ships.

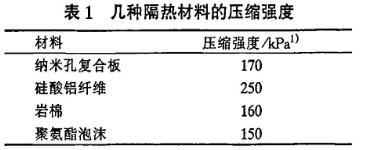

The strength of nano aerogel insulation felt with network structure composed of SiO _ 2 wall shell is often very low. Therefore, an enhanced treatment is generally required in making the product. Pow particles are typically use as filler aggregates and reinforced with fibrous material. However, the excessive use of reinforcing materials will increase the bulk density of nano aerogel insulation felt. And these reinforcing materials are relatively large in diameter, thus affecting the thermal insulation performance of the material. But it still helps the strength of the material. At the same time, in order to increase the strength, also have to use the product with glass cloth cover method. The existing nano aerogel insulation felt has a certain compression deformation problem, and the compression strength of of several non-rigid insulation materials is as shown in table 1

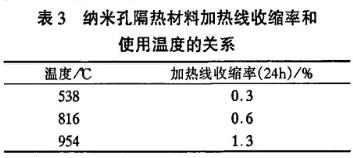

( 4 ) SiO _ 2 is the main component of nano aerogel insulation felt. Although the melting point of SiO _ 2 can reach 1700 ℃, due to the existence of some other chemical elements, the eutectic phase at lower temperature will be produced. At the same time, there will be crystallization in a temperature range below the melting point. Therefore, its actual use temperature is lower, generally considered at about 1000 ℃. See table 3 for the relationship between shrinkage rate of heating wire and service temperature of nano aerogel insulation felt.

3. Preparation process of nano aerogel thermal insulation felt

At present, sol-gel method and compression sintering method are commonly used in the preparation of nano aerogel insulation felt.

( 1 ) Sol-gel method

Ethyl orthosilicate, silica sol, water glass and the like are used as silicon source materials in the sol-gel method. Catalysts ( such as HCl, H2SO4, etc. ) were added to these sols, and then the gel time was adjusted by alkaline substances to form SiO _ 2 gel with nanoporous network. After aging, the SiO _ 2 particles in the gel form a network structure, and the voids in the network are occupied by liquid, i.e. water or solvent. If it is possible to keep the space originally occupied by the liquid replaced by air during drying, the SiO 2 material containing a large amount of air thus obtained is called a silicon aerogel. One of the key techniques in this process is that the gel shrinks and the nanoporous structure collapses during drying due to the capillary surface tension of the interstices. This causes the monolithic material to crack and eventually form a xerogel with a very low porosity. Therefore, the early research was carried out by supercritical drying ( SFE ). That is, in the supercritical state, there is no longer an interface between the gas and the liquid, but rather becomes a uniform fluid between the gas and the liquid, which is gradually expelled from the gel. Since there is no gas-liquid interface, there is no surface tension, and thus no shrinkage and structural damage of the gel is caused. However, due to the high temperature and high pressure conditions required for supercritical drying, the critical temperature of water is 274.1 ℃ and the pressure is 22.04 MPa; The critical temperature of ethanol was 239.4 ℃ and the pressure was 8.09 MPa. It is difficult to produce on a large scale. At present, only NASA use this method and ceramic fiber composite insulation tile is apply to that space shuttle. The rest is confined to laboratory research, and there are no commercial products. Now, a popular research method is to reduce the surface tension by surface modification. The gel surface is silylated with trimethylchlorosilane, polydimethylsiloxane ( PDMS ), etc. This reduce that surface tension of the capillary and thus reduces the shrinkage and crack of the gel during drying so that drying can be carry out under normal pressure. In addition, the bonding agent is added to increase the skeleton strength. However, the use of these methods reduces some of the thermal insulation of the material.

The nano aerogel thermal insulation felt made by sol-gel method can form thin-walled pores and ideal nano-pore network structure, so the performance is superior, but the cost is higher.

( 2 ) Die pressing sintering method

Another method of nano aerogel insulation felt is to use ultra-fine SiO _ 2 micro powder with chain-shaped plum as the main raw material, and carry out compression molding processing into a certain shape. And the original particle size of the chain structure of the SiO _ 2 micro powder is in the nanoscale range. Therefore, the pores of the network structure formed by the network structure are mainly in the nanoscale range. The key of this method is to connect these nano-sized ultrafine SiO _ 2 powders into a whole with nanoporous network structure. the best method is to make SiO _ 2 particles react with each other by sintering. Since SiO _ 2 particles are in nanoscale scale, controlling sintering temperature is the key to this method. In addition, fibers should be added to the raw materials to increase the strength, and opacifying agent should be added to effectively block the radiation heat transfer at high temperature. The properties of the products made by this method are generally slightly worse than those of monolithic products made by sol-gel method. Because the SiO _ 2 shell is thicker ( up to 20 nm ) than the SiO _ 2 shell by sol-gel method in this network structure, the heat conduction in the solid phase is increased. In addition, there are some micron-sized gaps between these powders, which also increase the thermal convection of air. However, the current nano aerogel insulation felt products are mainly produced by this method.

Rankings of similar articles

- Why not many manufacturers of nano aerogel insulation felt on the market?

- Nano Aerogel Insulation Felt is known as

- Comparison of thermal insulation effect of nano aerogel thermal insulation felt and other thermal insulation materials in petroleum pipeline

- The application effect of the nano heat insulation board on the industrial furnace is remarkable, and the universality is strong

- The nano aerogel thermal insulation felt has good thermal insulation performance, superhydrophobic property, long service life, compression resistance and easy installation and maintenance

- Can nano heat shields be used on ships and vessels and how?

- What is the effect of using nano thermal insulation panels in steel mills?

- What are the areas in which nano heat shields can be used ?

- Application example of nano aerogel insulation felt

- What are the characteristics of nano aerogel insulation felt? How?

Latest information

- Recruitment (Domestic Sales, E-Commerce)

- Italian customers come to visit our company and reach in-depth cooperation

- JinShi participate in 2016 international wall roofing materials production and equipment Expo

- Six Excellent Properties of Nano Aerogel Insulation Felt

- Nano Aerogel Insulation Felt is known as

- Comparison of thermal insulation effect of nano aerogel thermal insulation felt and other thermal insulation materials in petroleum pipeline

- The nano aerogel thermal insulation felt has good thermal insulation performance, superhydrophobic property, long service life, compression resistance and easy installation and maintenance

- Why not many manufacturers of nano aerogel insulation felt on the market?

- Characteristics and preparation process of nano aerogel insulation felt

- Can nano heat shields be used on ships and vessels and how?

Contact us

hotline:

86-132-806-65866

The phone:86-0533-2266502

add:Shandong zibo hi-tech development zone.