Nano Aerogel Insulation Felt is known as

Nano aerogel insulation felt as a new type of thermal insulation products have been unknowingly into various industries, mentioned nano aerogel insulation felt, through this name, we can understand the nano aerogel insulation felt and aerogel has inevitable connection, yes, its main material is si02 aerogel, in aerogel, and si02 aerogel as the main research object, si02 aerogel has the advantages of low volume density, low thermal conductivity, etc., currently in the field of energy-saving buildings, steel, aerospace and petrochemical industry, known as " magic material".

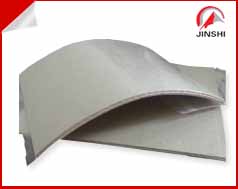

It's a " magical material" because it's only a fraction as thick as a traditional material, but it's 2 - 5 times better and lasts longer. In addition, its hydrophobicity and fire resistance are particularly good, and it is not surprising that it is popular with customers. Why nano aerogel insulation felt has such a good effect, this should start with the structure of si02 aerogel.

Si02 aerogel is different from porous materials with micro and millimeter pore structures. its fine nanostructures make the thermal conductivity of the materials very low, and have a large specific surface area. the scattering of light and sound is much smaller than that of traditional porous materials. The heat transfer of si02 aerogel is accomplished by solid heat transfer, gas heat transfer and radiation heat transfer. The pores of si02 aerogel and the curved path of the nano-porous network structure of fibers prevent the gaseous heat conduction of air and the solid heat conduction of gel framework respectively, and the thermal radiation can also be blocked by doping infrared absorbers. The combination of these three aspects, almost blocked all the way of heat transfer, so that si02 aerogel has a good thermal insulation effect. The thermal conductivity of si02 aerogel is below 0.013 w / ( m k ), which is far lower than that of static air at room temperature [ 0.025 w / ( m k ) ], and has the characteristics of low density, waterproof and flame retardant, green and environmental protection, acid and alkali resistance, corrosion resistance, aging resistance and long service life. The main component of the silica aerogel is si02, and the silica aerogel does not contain harmful substances to human bodies; and the obtained product has no radioactivity and is superior to the traditional heat insulation material. In addition, si02 aerogel has higher acoustic impedance, adsorption capacity than the traditional activated carbon adsorption material, the product has a high added value, so it is called super thermal insulation material.

However, because of its unique network structure, high porosity and low density, the semi-transparent si02 aerogel is very difficult to resist the influence of radiation thermal conductivity in high temperature environment. therefore, in many fields, si02 aerogel is difficult to be used as a thermal insulation material alone, it needs to be doped and modified or combined with other thermal insulation materials in order to achieve the ideal use effect.

Now you know why the nano aerogel insulation felt why so amazing, in fact, nano aerogel insulation felt is just one of many si02 aerogel insulation materials, the following small plait to introduce you to the preparation method of nano aerogel insulation felt:

Because pure si02 aerogel has very high transmittance to infrared ray with wavelength of 2 - 8 μ m, the heat radiation energy in this band will pass through the aerogel completely at high temperature, resulting in a sharp increase in the thermal conductivity of si02 aerogel. In order to reduce the radiation thermal conductivity, it is necessary to combine the opacifier which can absorb or scatter infrared light in si02 aerogel. Ti02 / si02 thermal insulation aerogels were prepared by sol-gel method. Ti02 and si02 sol were prepared respectively, aged for 24 h and then mixed. DCCA and DMF were added to form perfect gel network structure. TiO _ 2 / si02 thermal insulation alcohol gel was formed by placing. Then, the insulating TiO2 / si02 gel was soaked in TEOS ethanol solution, and the non-supercritical drying of the bulk TiO _ 2 / si02 insulating aerogel was realized by using the replacement of low surface tension solvent, graded aging and drying treatment. The obtained TiO _ 2 / SiO _ 2 aerogel is colorless or milky white light massive porous solid, and is prepared by dispersing TiO _ 2 and si _ 02 particles with a diameter of about 1 onm into each other, wherein the pore diameter is 20 - 40 nm, the bet specific surface area is 200 - 400 m2 / g, and the pore volume is l - 2 cm3 / g.. Tio _ 2 / si02 aerogel prepared by sol-gel method and non-supercritical drying has good transparency and certain mechanical strength, and can be used for decomposition of refractory organic compounds in photocatalytic wastewater.

Metal composite oxide insulated aerogels have high specific surface area and can be used as catalysts for higher education. However, in the process of solvent exchange and supercritical drying, metal ions will escape the gel, so usually only low metal content metal - si02 thermal insulation aerogel can be prepared, which can not achieve the desired catalytic effect. Chen Yimin et al. use n-propanol as solvent and hydrochloric acid as catalyst, that sol-gel process of Cu - TEOS, TEOS and wat at constant temperature ( 70 deg. c ) is carried out to form gel, and then the gel is aged at 30 deg. c for a certain period of time to prepare gel. the gel is put into a CD 2015 autoclave, and the aerogel is prepare by supercritical drying with ethanol. Placing the aerogel in a tube furnace, and carrying out high-temperature reduction under a hydrogen atmosphere to obtain the Cu - si02 nano thermal insulation aerogel with high Cu content, wherein the mass fraction of Cu is not more than 66 %. Cu - si02 nano-thermal insulation aerogel has a three-dimensional structure of nano-particles and nano-scale pores, the mass fraction of particles less than 25 nm exceeds 90 %, and the specific surface area is 400 - 650 m2 / S.. The insulate aerogel can be used as a high efficiency catalyst.

Si02 aerogel is prepared and then compounded with glass fiber cotton or preoxidized fiber felt by a special process to prepare the nano aerogel thermal insulation felt.

Rankings of similar articles

- Characteristics and preparation process of nano aerogel insulation felt

- Why not many manufacturers of nano aerogel insulation felt on the market?

- Comparison of thermal insulation effect of nano aerogel thermal insulation felt and other thermal insulation materials in petroleum pipeline

- The application effect of the nano heat insulation board on the industrial furnace is remarkable, and the universality is strong

- The nano aerogel thermal insulation felt has good thermal insulation performance, superhydrophobic property, long service life, compression resistance and easy installation and maintenance

- Can nano heat shields be used on ships and vessels and how?

- What is the effect of using nano thermal insulation panels in steel mills?

- What are the areas in which nano heat shields can be used ?

- Application example of nano aerogel insulation felt

- What are the characteristics of nano aerogel insulation felt? How?

Latest information

- Recruitment (Domestic Sales, E-Commerce)

- Italian customers come to visit our company and reach in-depth cooperation

- JinShi participate in 2016 international wall roofing materials production and equipment Expo

- Six Excellent Properties of Nano Aerogel Insulation Felt

- Nano Aerogel Insulation Felt is known as

- Comparison of thermal insulation effect of nano aerogel thermal insulation felt and other thermal insulation materials in petroleum pipeline

- The nano aerogel thermal insulation felt has good thermal insulation performance, superhydrophobic property, long service life, compression resistance and easy installation and maintenance

- Why not many manufacturers of nano aerogel insulation felt on the market?

- Characteristics and preparation process of nano aerogel insulation felt

- Can nano heat shields be used on ships and vessels and how?

Contact us

hotline:

86-132-806-65866

The phone:86-0533-2266502

add:Shandong zibo hi-tech development zone.