Overview of circular quenching furnace in Masteel

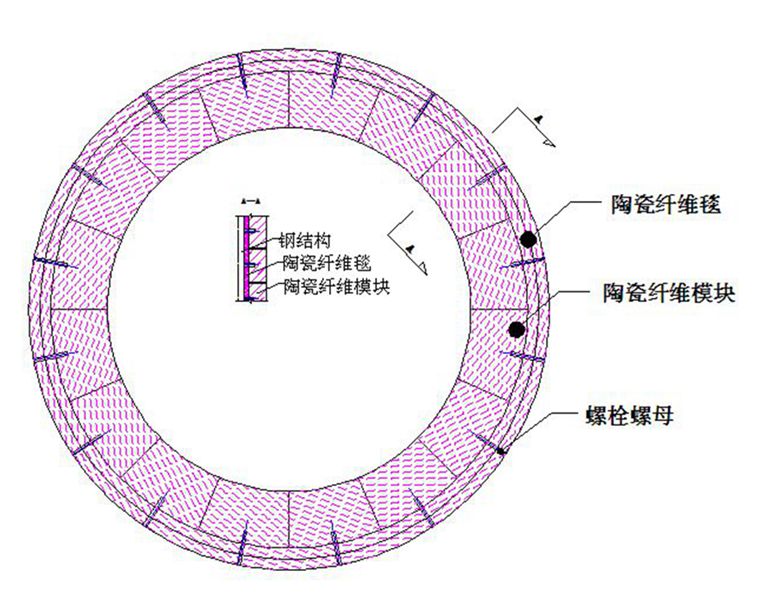

Masteel ring quenching furnace for continuous operation furnace, fuel using mixed gas, burner in staggered arrangement on the inner and outer ring wall, normal furnace temperature is 1000 ~ 1100 ℃, weak reducing atmosphere, micro positive pressure operation.

Consideration before transformation: comparison between heavy traditional lining and light ceramic fiber lining

Traditional lining structure: refractory brick and heavy castable structure

Disadvantage of lining insulation structure of traditional annular heating furnace;

1, The bulk density is big, resulting in furnace steel structure deformation is serious.

2, The lining of the thermal conductivity, thermal insulation effect is poor, resulting in furnace cold surface overtemperature ( up to 150 ~ 170 ℃ ) energy waste is serious, workers operating environment is bad.

3, Lining is difficult to overcome the ring furnace inherent defects of inner wall expansion, outer wall expansion.

4, Poor thermal sensitivity, to the ring furnace microcomputer operation has a certain negative impact, to a certain extent, affect the quality of the product.

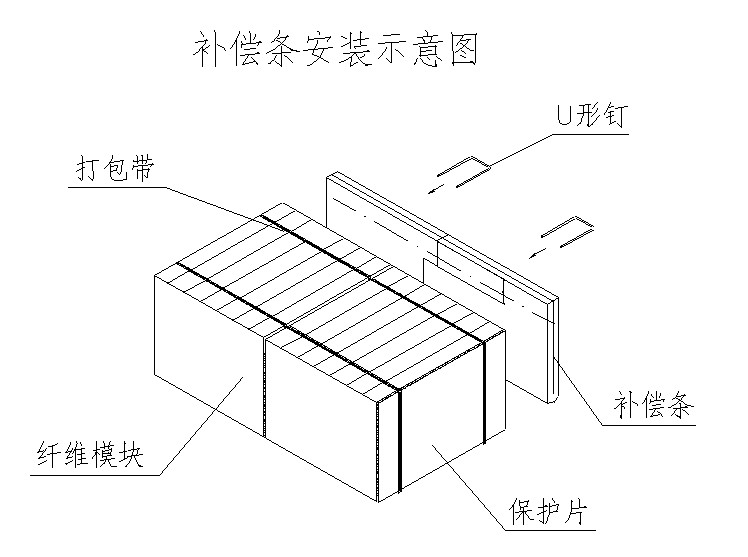

In order to meet the special structural requirements of annular furnace roof, ceramic fiber module is made into wedge-shaped structure, and the anchoring structure is slide type.

Technical advantage

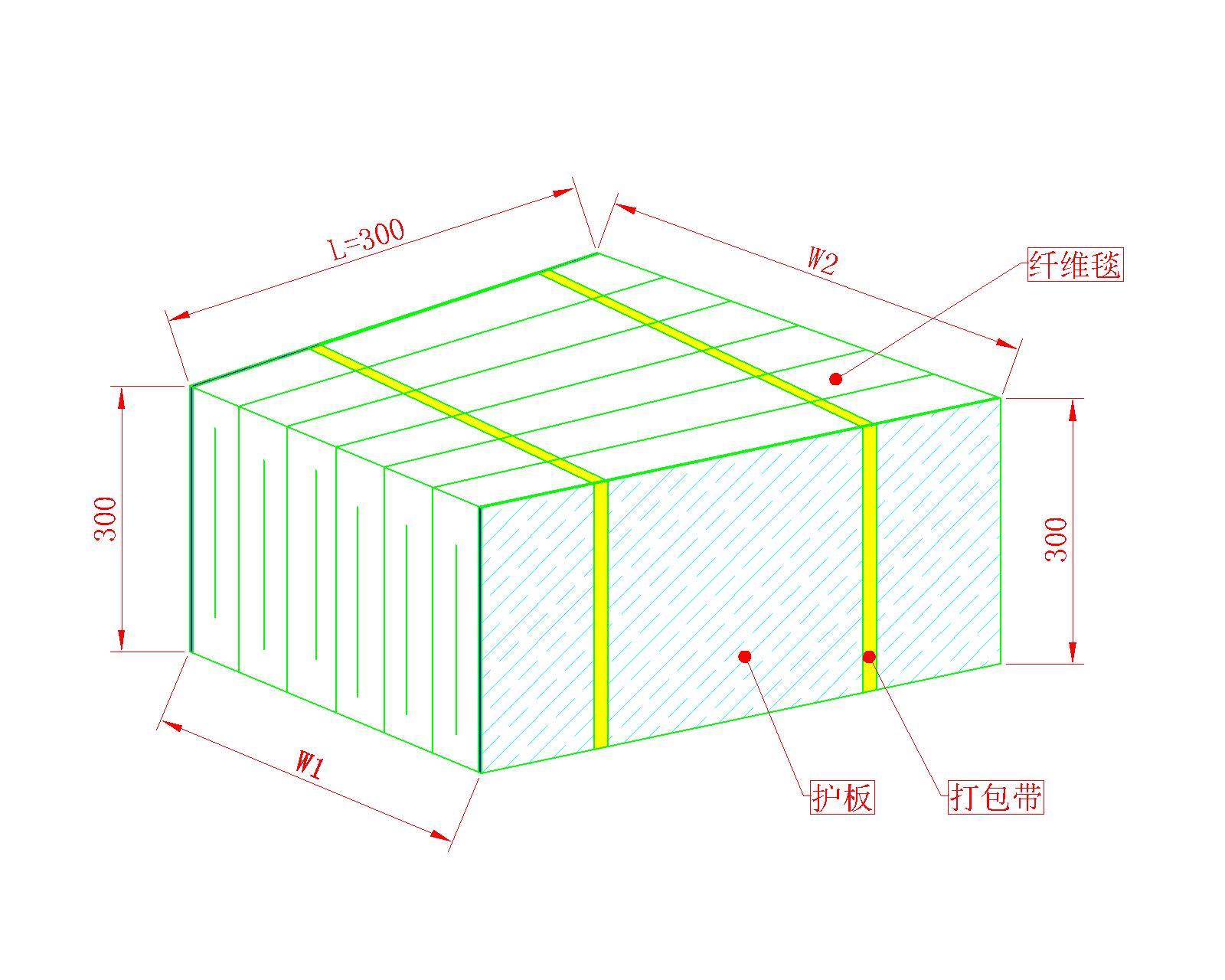

Wedge module for heat preservation of annular heating furnace, annular annealing furnace and annular heat treatment furnace: the aluminum silicate fiber module is manufactured into a wedge structure, which brings certain inconvenience to the processing of the module, but only when the module is processed into the required structural shape can the integrity and tightness of the lining be fully guaranteed; Avoid construction technical factors on the lining effect caused by excessive influence, ensure smooth construction ( such as the use of square module, close to the inner ring side by forced compression, easy to cause one end of the module damage or folding surface fracture, destroy the module structure, affect the module insulation effect ).

High temperature heat insulation solution for continuous casting and rolling bottom soaking furnace

High temperature heat insulation solution for coke tank cover