Overview on heat preservation of coke tank cover in coking plant

Coke tank cover as an accessory equipment of coke dry quenching hoist, its main function is to prevent the high temperature of red coke in the coke tank damage to the hoist and prevent dust float in the sky. Which mainly comprises a coke pot cover body, a sealing plate, a heat insulation material and a guide device of the coke pot cover. The main forms of coke tank cover are square coke tank cover and round coke tank cover.

Dry quenching coke tank cover insulation temperature:

Coke process refers to the pusher car will be about 1100 ℃ red coke pushed out by the carbonization chamber, the stop coke car coke guide grid, fall into the coke quenching car rotating coke tank, under the electric locomotive drag, led to the lifting tower, the elevator will coke tank to the upper limit of the lifting tower, and then translated to dry out the roof.

Coke pot cover long-term working temperature is 1100 ℃, generally not more than 1200 ℃, in order to avoid the reason of heat insulation materials lead to delay the use of the whole equipment, also in order to make the heat insulation materials to extend the working life to reduce the temperature risk coefficient, the vast majority of design institutes recommend using 1400 zirconium-containing ceramic fiber module + 1400 zirconium-containing ceramic fiber blanket, 1400 zirconium-containing ceramic fiber board as light insulation layer.

Ceramic fib heat insulation structure for coke pot cover

The refractory and heat insulation material of coke dry quenching tank cover is fixed by stainless steel mesh at first. in practical application, stainless steel mesh is easy to oxidize and fall off, which makes the dry quenching tower unable to work. After many tests, the company and the matched manufacturers finally decided to adopt the zirconium-containing ceramic fiber module, and the fixing bolt is wrapped in the heat insulation material, and has a certain distance from the hot surface, so as to solve the problem of high-temperature oxidation. the scheme has been affirmed by foreign customers in the elevator provided for foreign customers, and has been extended to this day.

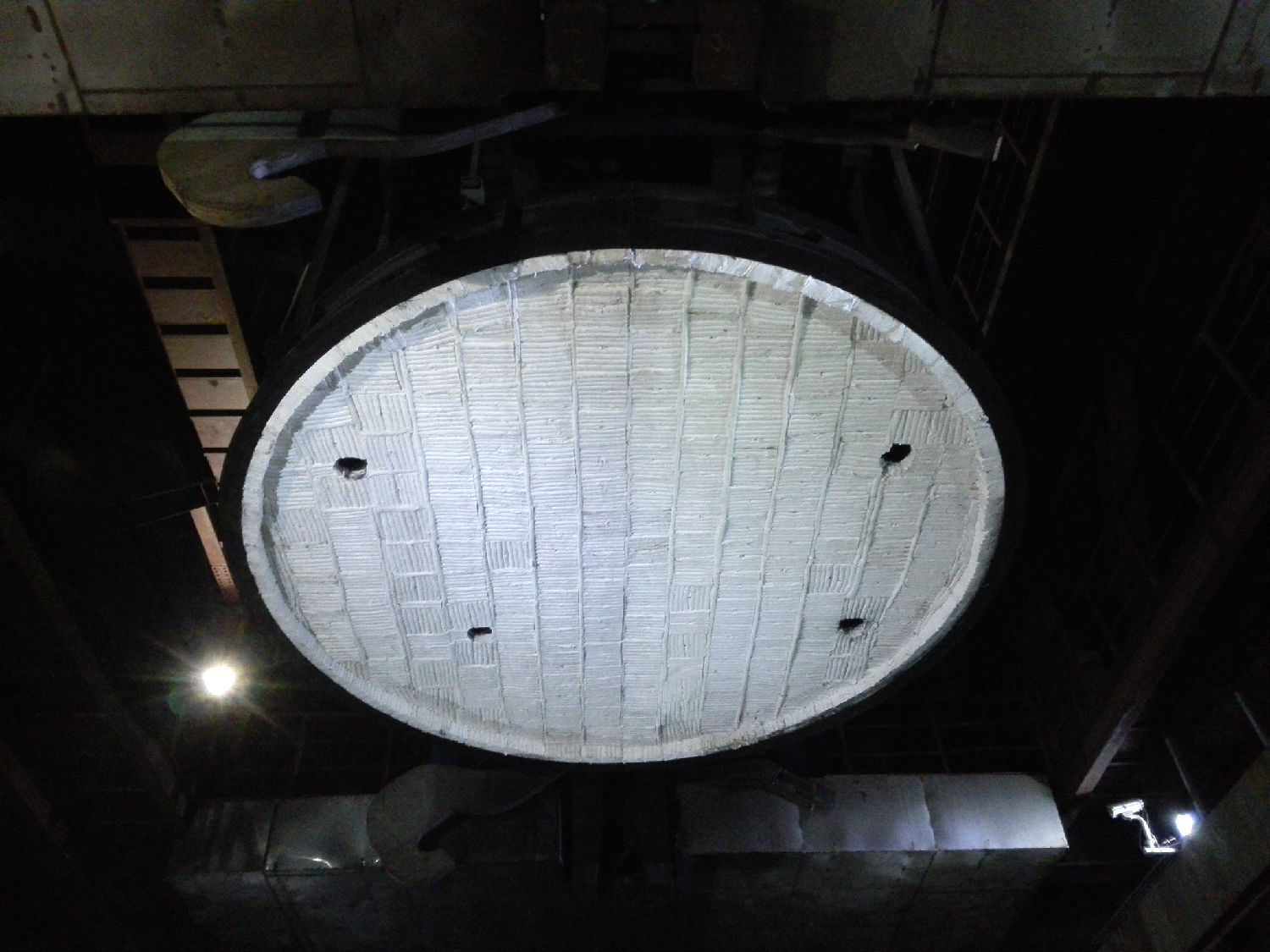

My company's refractory fiber material is mainly applied to the bottom of the coke can cover, that is, the side of the contact with the coke oven. At present, the main refractory material used in coke can cover is zirconium-containing ceramic fiber module, and the temperature resistance is 1400 ℃.

At present, our company for material and construction of coke can cover with zirconium ceramic fiber module, the main size is 300 * 300 * 200 / 180 mm, edge part is 150 * 180 / 200 * 150 mm, the actual situation to the customer coke can cover drawings shall prevail, supporting 310 s stainless steel anchor.

Thermal insulation layer laying - module composite lining structure of coke pot cover in coking plant;

Insulation layer: the total thickness of 200 mm / 180 mm / 150 mm;

Backing layer: using ceramic fiber blanket hlgx - 512 with thickness of 20 mm;

Hot surface: ceramic fiber module hlgx - 589, 180 mm / 150 mm thick;

Refractory cotton surface: besmear brushs a layer of high temperature curing agent.

Arrangement mode of ceramic fiber modules: adopt " soldier column type" arrangement;

Interlayer compensation blanket: ceramic fiber blanket hlgx - 512, fixed by u - shaped heat-resistant steel nail;

Site installation and transportation after installation adopt different schemes: coke can cover to be transported, and the butt joint of the two covers is wrapped with fiber cloth, so as to minimize the damage caused by collision during transportation and installation.

Coke tank cover regular maintenance

The heat insulation material on the heat insulation of coke tank cover is installed by module with density of 220 kg / m3, which fully conforms to the relevant parameters of the module specified in GB / t 3003 - 2006. Just installed module is soft, because of this characteristic to make its internal fiber is full of a lot of air, achieve good heat insulation effect, used module because of high temperature flame baking and a large number of flue gas curing reaction will make the heat insulation material gradually hardened, at the same time heat insulation effect is reduced, the service life of about 3 years. However, in order to ensure the best thermal insulation effect of coke can cover, it is recommended that the customer focus can cover refractory, besmear brushs high temperature surface curing agent once every six months for surface protection, or replace the ceramic fiber module once a year.

Technical advantage

1, cutting is convenient, dig a hole on the spot, meet the special requirements. The module at that explosion-proof hole is perfectly combine with the folding block, the hole is dug on the spot, and the prefabricate forming is not needed; One - step forming, time-saving and labor - saving; No waste, dig material can fill the center hole.

2, the use of fully automated heating furnace blanket heat treatment system, can be pre-treated fiber products crystal phase change, high temperature shrinkage is the lowest compared with similar products in the same industry.

High temperature heat insulation solution for continuous casting and rolling bottom soaking furnace

Energy - saving retrofit solution for annular heating furnace