Profile of furnace type

Thin slab continuous casting and rolling process is a relatively compact and efficient new furnace technology introduced in recent years. The method comprises the following steps: carrying out heat preservation or local heating on 40 - 70 mm thick slab cast by a continuous casting machine, sending the slab to a strip steel hot continuous rolling mill, and directly rolling the slab into 1.0 - 2.3 mm thick strip steel.

The normal furnace temperature of CSP line is 1220 ℃; Gas and natural gas are mostly used as fuel; The atmosphere in that furnace is weakly oxidizing. As a result of the above operating environment, the main lining materials of CSP line furnace technology ( loi, BRIC month, and techintalimpianti ) imported from abroad and home are all refractory ceramic fiber materials.

Thermal insulation of submerged arc furnace with continuous casting and rolling bottom - thermal insulation structure of ceramic fiber lining;

Heat preservation of submerged arc furnace with continuous casting and rolling bottom - heat preservation of burner part: light and efficient refractory ceramic fiber.

Heat insulation of submerged arc furnace with continuous casting and rolling bottom - heat insulation of furnace cover and furnace wall;

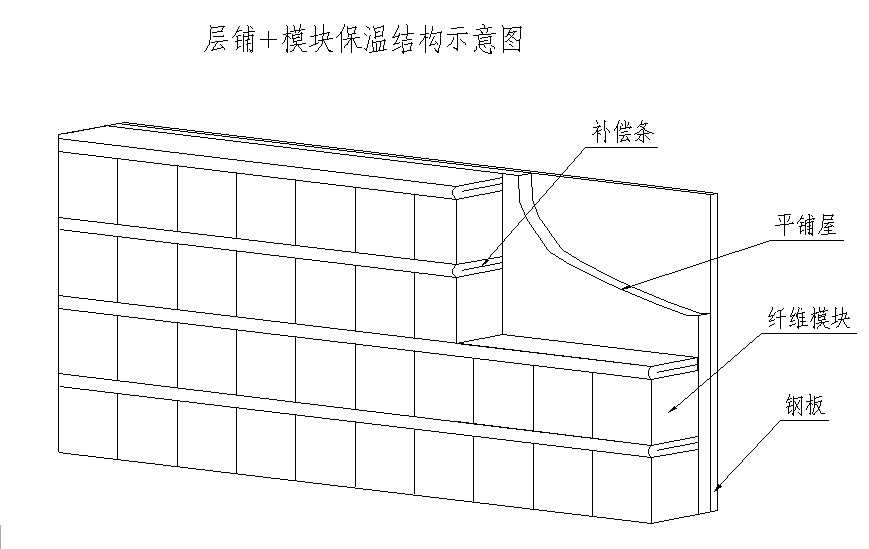

● selection of soaking furnace insulation materials: refractory ceramic fiber blanket hlgx - 512 and ceramic fiber module hlgx - 589 are used as lining structure.

● insulation thickness: the total thickness is between 280 and 310 mm.

● anchor material for lining: s310 material is adopted.

● module anchoring structure: butterfly anchoring mode is adopted.

Technical advantage

Butterfly anchor structure form:

The anchoring piece in the structural form is composed of a bracket shaped like a butterfly, two heat-resistant rigid tubes are welded, and ceramic fiber folding blankets with balanced compression amount are respectively inserted into the two sides of the steel tube. The aluminum silicate fiber module in the structural form not only has a firm anchoring structure, but also can ensure that the module is installed; after the protective sheet is removed, the compressed folding blanket can generate sufficient rebound, the expansion is completely not limited by the anchoring structure, and the seamless requirement of the lining is ensured; and meanwhile, because the ceramic fiber module and the backing layer only have a gap between a layer of steel plates, the ceramic fiber module and the backing layer can be tightly adhered to each other, and the thickness of the lining is uniform, flat and beautiful.

Connecting beam location:

Selection of heat insulation material: inverted t - shaped lightweight heat insulation castable prefabricated part is adopted

Insulation thickness: the total thickness is 355 mm.

Lining anchor material: s s s 310 material.

Prefabricated block anchoring structure form: y - shaped anchoring mode is adopted.

Arrangement mode of prefabricated blocks: upper and lower labyrinth lapping mode is adopted.

During construction, nuts are adopted to fix the prefabricated blocks with embedded bolts on the roof steel frame.

Technical advantages:

1. Labyrinth connection and good sealing: the inverted t - shaped castable prefabricated block structure, the lining at both ends of the furnace cover is buckled into the castable wall lining structure, so that the connecting part forms a labyrinth structure, and good sealing effect can be achieved.

2, Prefabrication, construction is simple: this part adopts castable prefabrication, construction only need to precast block fixed screw nut, gasket fixed to the steel frame structure of the roof, installation is very convenient, can greatly reduce the construction difficulty of pouring castable on site.

Furnace roller sealing structure:

Roller table heat insulation seal

The roller sealing block is made into two different blocks with semi-circular holes by using hlgx - 555 special-shaped part containing zirconium ceramic fiber, which are respectively buckled on the furnace roller.

Technical advantages:

Semi - circle phase buckle and convenient replacement: the sealing structure can not only ensure the excellent sealing performance of the furnace roller part, reduce heat dissipation loss, but also ensure the long service life of the furnace roller through soft sealing. And each furnace roll seal block is an independent individual, so that that furnace roll or the sealing material can be replace more conveniently.

Billet entrance door - fire curtain;

Our company according to the metallurgical large continuous operation furnace ( roller hearth furnace, step furnace, etc. ) introduced a simple and efficient door structure - fire curtain. The structure does not need a complicated oven door mechanism, is convenient to install and use, does not need to be assembled, disassembled and hoisted, can freely pass through the steel plate, can effectively block radiation heat transfer, resist corrosion, stabilize high-temperature physical and chemical properties and the like, and is used as a discharge ( feeding ) oven door of a continuous operation furnace; and the structure is simple, convenient, economic and practical, and is a novel refractory heat insulation structure application with great market value. ( see continuous heating furnace and heat treatment furnace for details ).

High temperature heat insulation solution for coke tank cover

Energy - saving retrofit solution for annular heating furnace